A Deep Study DTF Printing: Strategies, Advantages, and Sector Applications

A Deep Study DTF Printing: Strategies, Advantages, and Sector Applications

Blog Article

The Future of Style: Discovering DTF Printing Innovation in the Textile Industry

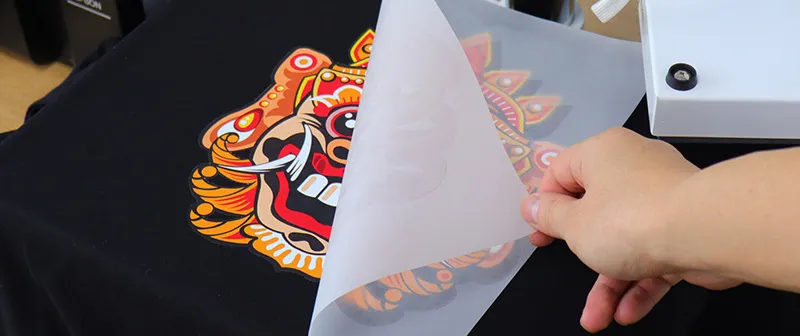

In recent times, the fabric industry has observed a marked change in the direction of ingenious modern technologies that are improving the landscape of fashion manufacturing. Amongst these developments, Direct to Film (DTF) printing modern technology has actually become a promising challenger, supplying special capacities and opportunities for designers and suppliers alike. This cutting-edge printing technique has stimulated rate of interest due to its prospective to transform traditional fabric printing processes. As we explore the effects and possibilities of DTF innovation in the realm of style, it becomes obvious that its combination might redefine industry criteria and lead the way for a new era of innovative expression and performance.

Development of Textile Printing

From the old people using techniques like block printing to the electronic transformation of today, textile printing has consistently pressed limits. As the craft spread to other parts of the world, brand-new approaches such as display printing and roller printing arised during the Industrial Transformation, changing the textile market.

The introduction of electronic textile printing in the late 20th century marked a substantial change towards more sustainable and functional printing techniques. The advancement of fabric printing showcases an abundant history of creativity, ingenuity, and technical progression in the globe of style and design.

Benefits of DTF Innovation

With the advancement of fabric printing strategies from old methods like block printing to modern advancements such as electronic printing, the intro of Direct-to-Fabric (DTF) innovation has actually substantially boosted the performance and sustainability of fabric printing procedures. Among the key advantages of DTF modern technology is its capacity to straight publish styles onto fabric without the requirement for transfer papers, which decreases waste and simplifies the production process. Additionally, DTF printing enables greater shade vibrancy and information accuracy contrasted to standard techniques, allowing textile producers to create top quality and intricate designs with convenience.

Moreover, DTF modern technology is recognized for its flexibility, as it can be utilized on numerous kinds of materials, consisting of natural fibers like wool, silk, and cotton, as well as artificial materials such as polyester and nylon (DTF Printing). This flexibility opens a large range of opportunities for producers and developers to explore different appearances and materials, leading to even more special and ingenious items in the fashion business. Generally, the implementation of DTF modern technology represents a substantial improvement in textile printing, using numerous advantages that add to the future sustainability and imagination of the industry

Sustainability in vogue Manufacturing

Highlighting eco-friendly techniques is paramount in modern style production, lining up with the growing customer demand for lasting items. Recently, the apparel industry has encountered increasing examination as a result of its significant ecological influence, consisting of too much water use, chemical air pollution, and textile waste. As an action, several fashion brands are currently incorporating sustainable methods right into their production processes to lessen injury to the setting.

Sustainability in vogue production includes numerous facets, such as utilizing recycled and natural products, reducing energy usage, carrying out moral labor techniques, and advertising transparency throughout the supply chain. Additionally, developments in modern technology, like DTF printing, offer chances to further enhance sustainability in textile manufacturing. This technology enables accurate printing on materials, minimizing ink waste and water use contrasted to typical printing approaches.

Layout Liberty and Modification

Furthermore, DTF printing facilitates modification on a scale formerly unattainable, enabling personalized apparel and special pieces customized to specific preferences. Customers can now proactively take part in the layout process, developing garments that show their design and character. Resources This customization not only enhances the customer experience but additionally promotes a feeling of exclusivity and uniqueness in a market filled with mass-produced apparel. Generally, DTF printing technology reinvents the design landscape in the textile sector, supplying countless possibilities for imaginative expression and customized style.

Effect On Supply Chain & Market Trends

DTF printing innovation in the textile sector is improving supply chain characteristics and influencing market patterns with its effectiveness and customization capabilities. By making it possible for on-demand printing and removing the requirement for large supplies, DTF modern technology improves the supply chain process.

In addition, the modification possibility of DTF printing modern technology is reinventing the market fads in the textile sector. Customers increasingly look for special and personalized products, and DTF enables brand names to provide custom styles cost-effectively. This customization ability not only improves customer contentment however also opens up new opportunities for services to satisfy specific niche markets and separate themselves from competitors. Therefore, DTF technology is driving a change in the direction of more ingenious and customer-centric strategies within the textile market, forming the future of fashion.

Final Thought

To conclude, DTF printing innovation is transforming the textile industry by using countless advantages such as design freedom, sustainability, and personalization. This cutting-edge modern technology is improving the future of style production, impacting supply chains, and driving market trends in the direction of much more effective and environment-friendly techniques. As the sector remains to advance, DTF printing will certainly play a look at here crucial role in shaping the means fabrics are generated and eaten in the years ahead.

From the old people utilizing methods like block printing to the digital revolution of today, fabric printing has actually consistently pressed limits. As the craft spread to other components of the globe, new methods such as screen printing and roller printing arised during the Industrial Change, reinventing the fabric sector.

The intro of digital textile printing in the late 20th century marked a significant shift towards even more lasting and functional printing techniques.With the evolution of fabric printing methods from old techniques like block printing to modern-day developments such as electronic printing, the introduction of Direct-to-Fabric (DTF) modern technology has dramatically enhanced the effectiveness and sustainability of fabric printing procedures (DTF Printing).In action to the imperative change in the direction of sustainability in style manufacturing, the adoption of ingenious innovations like DTF printing not only addresses environmental problems but likewise opens up avenues for unrivaled design liberty and customization in the fabric sector

Report this page